Ether and Ester-Based Polyurethane Foam: Characteristics, Differences and Uses

If an individual is told a product is made of foam, one of two mental images will likely arise; either the white polystyrene seen in drinking cups and coolers, or the squishy, soft material that makes up mattress toppers and polyurethane sheet packaging. While these are obviously both correct assumptions, foam is a surprisingly intricate material that can produce wholly different products through minor manufacturing changes. The familiar open-cell type of polyurethane foam used in bedding and cushions is actually divided into two sub-categories; ester-based polyurethane and ether-based polyurethane. If the two varieties were placed next to each other, the untrained eye would have difficulty deciphering any differences. And while the two types are similar enough to both be considered urethane foam, they each have their own set of traits that lend them to their own set of jobs.

On a basic level, both foams are considered urethane polymers, which is why their appearance, feel, and many of their applications are similar. Slight changes to the additives used in urethane polymers can result in the forming of hard plastics, soft foams, or anything between, highlighting the material’s versatility. The main differences between the two polyurethanes are their bases; polyether triol for ether-types and polyester for ester-types. Through chemical reactions, these mixes expand and eventually form types of the polyurethane foam materials we are familiar with today.

Ester-based polyurethane was the first of the two foam types, being developed full-scale in Germany after the end of World War II. The material was in earlier stages of development before that, but the materials and resources needed to create the material were monopolized by the war. Ether-based polyurethane soon followed and, particularly through its hard plastic formulations, revolutionized the textile world. Today, ether-based polyurethane is used more predominantly because the raw materials required in manufacturing the ether-type cost less than ester-based polyurethane. Ether-based foam also better withstands hydrolysis, which is the breakdown of molecules in contact with water. However, ester-based polyurethane retains its own unique qualities that provide better performance in some applications than ether-based foam.

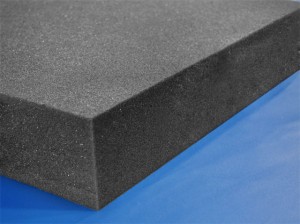

While still soft and compactible on the full spectrum of foam, ester-based polyurethane is slightly more rigid and supportive than its ether counterpart. This is a result of its forming process generating a smaller cell structure. While still open-celled, these smaller bubble-like cells are more difficult to bend and flex than the larger ether-based cells. This results in ester foam being a slightly better shock absorbing material, one reason it is often made into charcoal packaging foam. That shock absorption along with its firm and supportive structure makes it excellent for safely securing items in transit and protecting those in storage. It is also often treated with agents to create pink Anti-Static foam that dissipates electro-static charges in sensitive electronic equipment or instruments. Because of its greater rigidity, ester-based polyurethane is also often made into cleaning products like sponges and mops. The tensile strength and durability of ester-based urethane is also greater than ether-based urethane.

Ether-based foams however, are more flexible, better at handling wet environments and, for the most part, are produced more affordably than ester-based foam. Ether foams also have a larger cellular structure than ester, which allows greater airflow and moisture permeability through its form when in use. This makes ether-based polyurethanes excellent for speaker foam, aquarium filter media* or air filter foam. Ether-based foam is also made into a special kind of foam called Dryfast foam, which features an open structure to allow the flow of water and air through its form, keeping it from retaining moisture and helping it dry quickly. This foam is well-suited for marine cushions in boats and outdoor patio cushioning, where moisture is constantly around the products. Softer and smoother than ester-based polyurethane, ether-based foams are more frequently used when a material is in greater contact with its environment. Colored polyurethane foam sheets mounted for acoustic improvement are an example of this. All of The Foam Factory’s open-cell polyurethane foams are currently the ether-type because of its greater versatility.

As is true in most situations, a little information can go a long way. Understanding the differences between these two very similar materials and how they impact performance can help you chose the best product for the job. To summarize, this is a condensed list of the qualities and characteristics for both varieties of foam:

Ester Traits:

- Less Prevalently Used

- Rigid and Supportive

- Greater Tensile Strength

- Slightly Smaller Cells

- Used For Specific Jobs

- Susceptible to Hydrolysis

- Costlier To Manufacture

- Older

Ether Traits:

- More Prevalently Used

- Softer and Cushioning

- More Flexible

- Larger Cells

- Wider Range of Applications

- Resistant to Hydrolysis

- More Affordable

- Newer

*The Foam Factory’s Filter and Dryfast Foam has not been tested for use in aquariums. Always test filter media before installing in an environment with aquatic life.

Tags: Anti-Static, Filter Foam, History, Open-Cell Foam, Promotional Product Packaging

Posted in Announcements

I would like to know which one would you recommend for cleanroom packaging products ?

Ester foam or Ether foam ?

Hi Yan,

To our knowledge, there isn’t a marked difference between the two styles of foam in regard to a cleanroom situation. Different foam products themselves, however, can make a difference. We currently only offer ester-foam types, and would suggest our plastic-like foams for cleanroom-type applications. Open-cell foam, when it begins to severely break down, will produce a dust, whereas closed-cell types mainly rip and tear over time without creating any debris. Our closed-cell polyethylene foam most closely fits that bill. It is non-dusting and more plastic in nature than traditional open-cell packaging, and will not crumble into pellets like white beadboard foam either.

I’ve sent your inquiry to our Sales Team who should be getting into contact with you soon for a more in-depth look at your needs. I hope this helps, and feel free to Contact Us if you have any additional questions!

-The Foam Factory

Is Ether foam recyclable? Can you please provide information…..

Hello Carol,

Thanks for posting on our blog. Ether foam’s capacity for being recycled is found more in its ability to be repurposed and reused, rather than being broken down and turned into something new again. Larger foam products produce scrap foam that can be cut into smaller products, such as a mattress leaving a section of scrap that can be carved into pillows.

When things become too small to be cut into solid products, they are then shredded, which allows the material to be used as a fluffy filling or stuffing in pillows, foam bean bag chairs, or any other comfort product. After that, you can still be left with pieces not suitable for shredding, or foam that may have been damaged during delivery or warehousing. In these cases, the foam is compacted, lashed into large bales, and sold to manufacturers who shred this material on an industrial scale, compress it, and bond it with adhesive, to turn it into a high-density bonded foam – commonly seen as carpet padding for one example.

At a certain point foam does break down, and it will need to be disposed of, but there is a life cycle present in foam, and it is nearly a zero-waste material in the sense that every part and piece of it can be put to use in one way or another. If you have any other questions, just let us know!

-The Foam Factory

Hello, the life of ester foam has how long before is breaks down?, ive opened old vcr tape recorder cases to find the foam they used in the 80’s had turned to dust.

Typical life of polyurethane foams ranges from about 2 years to 15 years depending on the quality of the polyurethane. After that then the foam does eventually break down similar to what you are describing.

I’m curious as to which type of foam is better to use as baffling in fuel tanks. Does one type of foam degrade faster than the other when saturated in gasoline? Does the fuel octane influence the degradation rate?

I am sorry, we do not carry foam baffles that can be used in fuel tanks.

I need to replace the foam in my Whirlpool Dryer blower assy. What is the best foam – ether or ester polyurethane foam?

Both foams would be OK. We carry only the ether polyurethane foams.

Are the open cell foam treated with anything like mildew resistant, or fire resistant material? Is it just pure polyurethane foam?

Some of our foams are fire retardant and / or mildew resistant. Our data sheets state what features the foams have.

What is the life of polyurethane foam used in fiberglass boats in 1973? Does it actually disintegrate over time?

Yes, after about 20 to 30 years nearly all polyurethane foams will begin to disintegrate. Typical life for most foams can range from 2 years to 15 years depending on the quality being used.

I am looking for a fairly dense ether foam that is in about 8ft by 4ft sheets about 4 inches thick for Archery targets.

We are an Field Archery Club in Surrey and the black sheets we bought are only just starting to be shot out after about 10 years which have given us fantastic service in our woods in the open air.

We have our standard archery targets. Or you can use our polyethylene foam in any density about 4lb to make your own archery targets.

I work in a museum and we are in need of packing foam to line shipping crates. open cell. charcoal. I’m confused about ester vs. ether foam. would either one be o.k. to use to line crates?

I would be using hot glue.

Either foam type should be OK for packing applications. All the foams we carry are ether based. Yes you may use hot glue to glue the foam.

Please to tell the lifetime of the foam…

The datasheets in our General and Technical Information section does mention the typical life expectancy of the foam.

I have a large case to store and transport a telescope—70 to 80 pounds of very delicate optics—and I’m looking for a good solid foam that I can attach to the inside walls, floor and lid of the case.

I’m thinking that what might work best is the same solid type of material used in the charcoal-colored “pic-n-pluck“ stuff (often used for camera and other optical cases), but I need solid sheets instead. Also something not subject to out-gassing over time.

What can you recommend?

Thank you in advance. I would forward to hearing from you so I can place an order soon.

Dennis Mammana

I would suggest our charcoal firm foam for your application. If you want a closed cell foam instead of an open cell foam, then I would suggest our cross linked polyethylene foam.

I need a polyethylene/char/ester foam 5/16 inch thick. I have a physical data sheet or what Im using now. If you will kindly email me your fax number I can fax you this sheet. thanks much

Please see our contact us page.

Is this charcoal based ester foam, ESD dissipative?

All the polyurethane foams we carry are ether based. We do carry pink anti-static foam in both ether-polyurethane and polyethylene variants.

Can we make rebounded foam blocks from Ester also? like it is being made from Ether foam trims.

I am sorry, at this time we only carry ether foams.

Good morning ,

I am looking for a quote on the following material, please.

Our P/N 33172 foam .3125” thick, 54” wide , 50 ft, .256/ sq 1.3 # 30 ILD Ether open cell foam,APPROX. PPI 50

If you can provide , please give me a price , lead time and minimum order qty if it applies. Thank you

Please Contact Usfor pricing information.

I’m looking for an outdoor foam to cut and fit around raised shutters on the house to keep them from building nests behind them. I’d like to find something long lasting,water & weather resistant and brown or dark in color. FYI, the house has a stone facade and the foam when wedged behind the shutters would have to form to the stone. What would u recommend? Thanks

For your application, we would recommend our Neoprenefoam, but you would need to test to make sure the product works appropriately for your application.

Hello,

I have acquired a lot of ester charcoal packing foam (from many Pelican cases) as they were destined for the landfill. Would these be a poor choice for acoustic treatment for a recording room? Would Ether foam be a better choice? Should I also worry about their degree of flammability? Thank you so much for any information!

Please Contact Usfor further information regarding your application.

how well does the polyether polyurethane foam hold up to 50% caustic solution at room temperature?

What is the expected life time if completely immersed in 50% caustic at room temperature?

We are sorry, but we do not have experience in this area. You will need to test the foam for your specific application.