Taking a Closer Look at Foam: Part 1 – Open-Cell Foam

If you were to survey a handful of people on the street, you would be hard-pressed to find a person who doesn’t know what you’re talking about when you say the word “foam.” However, part of what makes this material so interesting is that while everybody knows what foam is, the type of foam people first think of can generate all kinds of different answers. One person could envision memory foam or polystyrene just as easily as another could think of neoprene or gym rubber.

Of course, one type isn’t more correct than another, but with this amount of diversity, there is a bit of ambiguity that can accompany the term. Here at Foam Factory, Inc., we wanted to offer a more detailed glimpse into the structure of our materials, so you can see some of the characteristics that help define the foam you’re familiar with.

Open-Cell Foam

Traditional polyurethane foams are very similar structurally, providing a recognizably soft and squishy feel. Colors aside, Foam Factory’s memory foam, Lux foam, HD36 foam, charcoal foam, and poly foam varieties are all similar on a cellular level, though the compounds used to make the materials may differ.

Foam cells, both open and closed, are bubbles that have expanded from the liquid mixture of the foam during its formation. In open-cell foam, these bubbles expand until they burst, leaving behind an interconnected structure of foam called struts. In closed-cell foam sheets, cells do not rupture, and the thin surfaces between the struts are called windows.

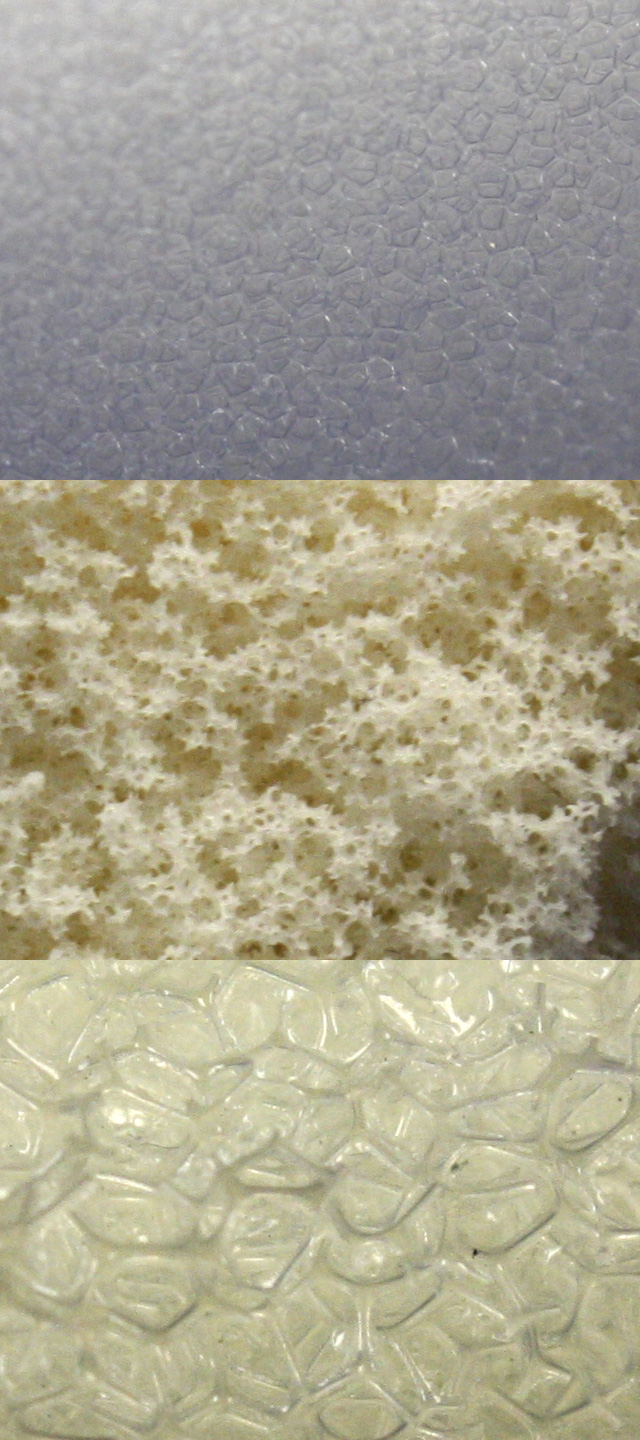

Without holding a polyurethane open-cell foam sheet inches from your eyes, you likely won’t notice the material’s structure unless you’re specifically looking for it, save for a few of the larger ruptured cells. These foam cells are smaller than a millimeter in length and create a structure that’s very consistent as a whole. If you inspected a cross-section of open-cell polyurethane foam with a magnifying glass, you would see a structure like in the picture that looks like millions of popped bubbles stuck together.

Depending on the cutting process of a material, some polyurethane open-cell foams look like they sparkle. This occurs when the foam surface contains the aforementioned windows that didn’t rupture in the foam’s formation. These reflect light, making them noticeable when looking across the form, but are minimal compared to the actual number of cells in an open-cell material. Over time, these remaining cell walls break down with use, giving the foam a flatter, more matte-like appearance.

Latex foam is another variety of open-cell foam, and is very similar to polyurethane foam with a few minor differences. Depending on the type of latex, some of the cells may be slightly larger than those in polyurethane foams. This varying cell size, combined with its cream color, gives the material a fluffy appearance, a lot like Angel Food cake. One distinct quality about latex that sets it apart from other open-cell foams however, is the way it’s made. Poured into a pincore mold, spots evenly dot the surface like ventilation openings. The metal pins that make these holes are slightly smaller in diameter than a pencil, and depending on where a cut is made in the foam, the canals left in the material for ventilation may be obvious because of the depths to which they extend. They are an important part of the material’s formation however, and should not in any way be considered a defect.

Dryfast foam is easily the most unique material among Foam Factory’s open-cell foam types. Designed to permit the passage of both water and air, the cells of Dryfast are easily seen with the naked eye. Juxtaposed against traditional polyurethane foam materials, these cells are massive, with some being 3, 4, or 5 millimeters in diameter. The thin cell struts, compared against the comparatively large pores, almost make Dryfast appear wiry. Despite that, Dryfast is strong enough for use in outdoor seating cushions and marine foam pads, attesting to the resilience of the material.

—

For the next post in our two-part series, click here: Taking a Closer Look at Foam: Part 2 – Closed-Cell Foam

Tags: HD36 Foam, Latex Foam, Lux Foam, Open-Cell Foam, Poly Foam, Polyurethane Foam

Posted in Announcements

Leave a Reply