Making Sense of Open-Cell Foam Densities

When dealing with foam products, knowing a material’s density but not how that value compares to others is a lot like being given a car without the keys. Sure, it’s cool, but how are you supposed to use it? Without having a solid understanding of the scale density values are measured on, knowing the numerical density of a foam product is pointless. (It’s also important to understand that density is fully independent of firmness/feel. For a more in-depth look at the differences between density and firmness, check out our previous post on the topic.)

Take the following example: if you know density is representative of the weight of a 12″ x 12″ x 12″ sample of foam, and a 2.8LB density value for open-cell polyurethane foam is considered high-quality (it is), you’re ahead of the game. But when you think of 2.8 as just another number on the density scale, you realize you need to know the typical range of values on that scale to make comparisons with any degree of accuracy.

With a clear explanation of the typical range of open-cell density values, and a simple three-category breakdown, this article should help you make informed decisions and get you the right foam for the job.

Fair Quality: 0.8LB – 1.2LB Density

Foam in this range is considered low density and fair quality, primarily intended for specialty applications and lighter use. These low-density materials carry less physical foam mass compared to higher densities, making them susceptible to breakdown more quickly.

Fair-quality foams can serve many purposes however, and their low-density affordability makes them a great material for many jobs. For example, a low-density material is excellent as one-time packaging for shipping, or for protecting infrequently-used items in storage, like holiday decorations. With a cost less than that of high-density materials, you can get all the performance you need from a more affordable product.

Lower density foam also makes sense in occasional-use comfort products. A low-density mattress topper will soften the hardest guest room beds, saving you the expense of replacing a bed that only gets used a few weekends each year. With infrequent use, the foam will hold up much longer than it would were it to be used in your own bed each night. Pairing fair-quality foam with the right application gives you functionality and affordability, providing plenty of value for products in this range.

Good Quality: 1.3LB – 2.4LB Density

Foam within this range is medium-density, and should be considered good quality. In this range, you’ll find a more resilient group of products that hold up better to more vigorous and frequent use. By bridging the gap between fair- and high-quality foam, this medium-density range generally has the broadest span of material quality from its low to high end. Fortunately, foam density has a linear relationship with quality, so the greater the number, the more durability and resilience a product offers. Essentially, “bigger is better,” when dealing with foam density.

Many of the conventional foam products on the market are made from materials that fall in this density slot. However, some retailers like to claim their 1.8LB foam is high-quality. This is exaggeration. It very well may be the highest quality foam they offer, but there remains a higher tier of foam density available to those who want the top-quality open-cell foam for the most demanding applications.

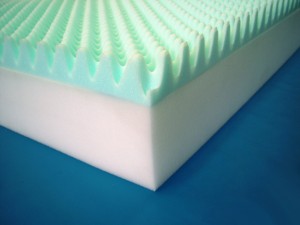

Foam in this range is still good-quality though, and many types at the higher end of this range are made into cushions and pillows. Frequently used packaging made from materials at the lower end can maximize bang for your buck with reusable performance as well.

High-Quality: 2.8LB – 3.5LB Density

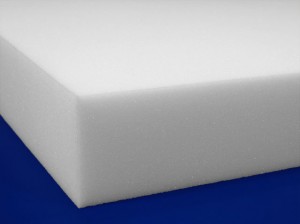

You’ll be hard-pressed to find everyday products in a density or quality greater than the materials in this segment. Compared to the lowest density materials, high-quality foam can have as much as three times the foam mass in the same-sized product.

Products with a density in this range offer the greatest quality and are the most resilient products available, making them perfect for high-abuse jobs like cushions and mattresses, especially when you want additional resilience over what medium-density foam can offer. In many ways, products in this range can be looked at as an investment. They will carry a heftier price tag than lesser materials, but it represents the cost of greater longevity and performance. In comfort and support applications, high-density foam in this range represents the best conventional open-cell foam has to offer.

As you can see, a half pound of density, or even just a tenth of a pound, goes a long way in the world of foam. With a majority of products falling between 1LB and 3LB density, understanding the degree to which a seemingly small numerical difference can make will give you the ability to find the right foam product for your needs.

Tags: Comfort and Support, Foam Sheet, High Density Foam, High Quality Foam, Open-Cell Foam

Posted in Announcements

looking for a product we can make archery targets and Boogie boards.

Both projects will be outside use on the Oregon Coast.

Were looking for 2″ thick High density, that is what Ive seen in similar targets and boards. We will be building our own targets and boards.

What size does it come in, what density and colors?

Respectfully,

Ron Stroh

We would suggest our either our 4LB polyethylene foam or 3.8LB Minicel EVA foam for your application. Link is included for sizes and pricing.

I am repairing my sea doo seat. Need to know which foam to use the previous article stated open cell

For Sea-Doo seats, we actually recommend a water-resistant closed-cell foam. The foam that we typically see used for this application is our Minicel T200foam.

Hi,

I am looking to alter a motorbike seat.

The bike will be used for touring so I will be sat for hours.

What type of foam do you suggest?

Would I be better using a layered approach

Thanks

Rob

For this application, we would recommend a layered cushion with our Minicel T200as a base and our Super Maxfoam on top.

I am looking for a block of open-cell foam that is a bit denser than whatever foam the classic ‘foam brushes’ are made from (black foam brush on a round wooden handle, for painting, glueing, automotive and maritime)

These are the ones I’m thinking of:

https://tinyurl.com/3uckkz5u

Can you guide me to a denser foam?

Thans, S

Hello Sune.

These sponge brushes are made of a Regular Charcoal Foam. Keep in mind that the thinner the foam, the softer it will feel. The next firmness up from this would be our Charcoal-Firm Foam, however if you are wanting firmer than that the next option would be Super Lux.

You can purchase Samples Kits of these foams on our website to test out before purchasing standard sheets.

If you have any further questions, feel free to contact us.