Insulate and Protect Your Hot Tub With a Custom Polystyrene Cover

While enjoying outdoor swimming pools and beaches can only happen during the summer months, there is one way people relax and unwind in the water year-round, and that is in their hot tubs and spas. With uses ranging from physical therapy and medical purposes, to entertaining and relaxation, people enjoy their hot tubs under summer stars and winter snow. Potentially the most important factor to enjoying a hot tub year-round is its cover. Even while being the only component not in use while people are in the water, covers insulate temperature to save energy and protect the water during the other 99 percent of the time it isn’t being used. That, in addition to the beating they take from the elements, means covers must stay in top shape to ensure the rest of the hot tub does as well.

At The Foam Factory, we possess the materials and manufacturing capacity to create hot tub cover inserts, so you can get the most enjoyment out of your investment!

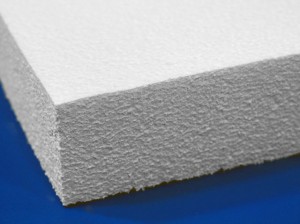

Expanded polystyrene (EPS), commonly known as polystyrene, is the standard filler material for hot tub covers because of its insulation capacity, rigidity, and resistance to moisture. With a closed-cell structure that will not permit the growth of mold, mildew, or bacteria, polystyrene covers will not rot or prematurely fail in the line of work. Any hot tub covering material without these characteristics is not suited for the application because of the constant exposure to moisture, condensation, treatment chemicals, and humidity.

Another quality of polystyrene that boosts its functionality as hot tub and spa covers is its material density. All polystyrene foam is not the same, with different densities of the material that allow users to tailor the foam to their particular use and budget. The Foam Factory’s 2LB density is specifically used for hot tub and spa cover usage. Many cheap covers exist that are made of 1LB density, but with the foam being lower-performance material, it doesn’t always provide the insulation and vapor barrier hot tubs require to run efficiently. 2LB polystyrene insulation packs more material in the same dimensions, insulating better and keeping treated water from evaporating.

The Foam Factory’s 96″ x 48″ hot tub covers feature a taper of 3.5″ to 2″, allowing water and debris to run off the top of the tub. At this size, you can trim the insert down to the dimensions of your cover at home, slide them into its cover, and have a great replacement piece!

Damaged, old, or cheap hot tub spa covers can drive up the energy cost of heating water, as well as allow insects, dirt, and other debris to enter into the tub. If you’re looking to replace an existing hot tub topper or purchasing your first, The Foam Factory has you covered.

Note: Hot tub covers are currently pick-up only at our Macomb, Michigan location.

Tags: Closed-Cell Foam, Custom Cover, Hot Tub Cover, Insulation, Polystyrene

Posted in Other Products

I am looking for the vapor wrapped inserts for my Nordic hot tub cover. Does your company sell those?

Hi Sandra,

Yes, we do offer plastic vapor wrap on our hot tub covers. Simply mention that you would like vapor wrap when placing your order, and we can add it. I’ve sent your message to our Sales Team, who will be getting in touch with you for more information regarding your cover!

-Foam Factory

Hi I need one insert for my hot tub cover. Do you sell them . Size 35.15 x 62 thickness 3in to 5 tapered ….thankyou

We sell this product for local customers. Please contact us for details.

please quote

1 off polystyrene spa cover (Round)

2000mm diameter

optional delivery to Pottsville NSW 2489

Please contact us directly for pricing.

Hi,

I am looking for replacement foam for my hot tub, the size is roughly 2000x1000x75mm, can you give me an estimate including the barrier wrap on the foam.

Thanks

Sharon

Please contact us directly for pricing.

Hi,

I need an insert for a round hot tub cover . 6 feet in diamatwr including a 2 inch middle divider. 4 Inch to

2 inch taper . Thanks

Please contact us directly for information and pricing.

Do you sell and ship hot tub covers?

At this current time, these are pick-up only at our Macomb, MI location.

Hi I’ve managed to damage one side of my hot tub lid which is 2m x 1m I’ve broken the foam inside the cover and it’s 4” thick I think can you help kind regards

Please Contact Us for information regarding your inquiry.

What is the reason for not shipping Hot Tub inserts?

We are only able to ship our Polystyrenefoam in sizes of 24″ x 48″ due to shipping restrictions.

i have a vita vista hot tub it measures 85″x85″ i need 1 side foam insert 85″x42″ 3″ to 2″ taper with 3″ radius on 2″ ends with plastic barrier on it . how much would it cost for one.

Unfortunately, due to shipping restrictions, we are only able to ship our Polystyrene foam in 24″ x 48″ pieces.

Where are you located? I need EPS for one side of my spa only, plus sealing. The second side is not waterlogged. I would like to bring in the template if you are located in California.

Please advise

We currently only have one location in Michigan. All of our information can be found on our Contact Uspage.

Hello, I have a 8×15 swim spa in my garage. Looking for a lighter solution to a cover. Was wondering since it is indoors out of the elements if I could just use 4 4×8 sheets of the insulation and just pull them off one a t a time, instead of the weight of a conventional cover. Thank you

Please Contact Usfor further information regarding your inquiry.

Hi I want a hot tub cover for my inflatable hot tub but i want it in two Half’s so that I can easily remove it as it’s under an igloo and difficult to remove and replace the original due to limited clearance so basically a round thick piece of foam cut across so it’s two halves for easy removal instead of using the standard inflatable ring that is supplied with the hot tub hope to hear from you

Kid regards

Roy swain

Please Contact Usfor more information regarding your inquiry.

Looking for a custom size Polystyrene Cover measuring 68″ x 37″ shipped to Seattle (98117 zip code). Can you help?

Please Contact Usfor more information regarding your inquiry.

Looking to replace insulation in my hot tub cover. Looking for 2 sheets 2” thick

3’x6’1

High R value

Hello,

Thank you for reaching out to The Foam Factory via our blog.

For hot tub covers we would suggest using our 2LB Polystyrene. You can see our available sizes and pricing using the website: Polystyrene Foam, High Density Closed Cell Foam, Polystyrene Sheets (thefoamfactory.com)

For all future questions, please contact us.

Is the 3.5″ to 2″ taper all you have. My cover needs a 4″ to 2.5″ taper. It is 93 3/4″ x 56″.

Thank you for reaching out to The Foam Factory via our Blog.

Per your question, yes, we only offer one size hot tub cover 96” x 48” and the taper is from 3-1/2” to 2”. This is also for pick up only. We are located in Macomb, Michigan USA.

If you are local to us, you can stop in and see if we can cut a custom foam piece for you. Or we can provide the foam for you to cut on your end.

For all future questions, please contact us.

I noticed that shipping comments are old. Can you ship yet to Ohio. Need 4” to 2” taper 7’ by 3.5’

Sorry, only local in Michigan.