Climb Higher With Confidence Using Bouldering Crash Pads

As people focus more on their health with fun, exciting ways to stay active, rock climbing has become a particularly popular recreational activity over the last few decades. As the number of people participating in this hobby increases, it makes sense that the potential for injuries is greater than ever before, based solely on numbers. Combining that increasing number of climbers with their inexperience, it’s not hard to see why injuries connected to this activity are on the climb as well.

Fortunately, there are plenty of ways to enjoy yourself while staying safe as you take on the challenge. The simplest and first step to take in rock or wall climbing is to give yourself plenty of time to get used to even the most basic climbs and to always practice with others, while listening to the advice of more experienced climbers. This is more common sense than anything, though it can prevent a majority of accidents. When you’re prepared to take on a greater commitment to climbing, one of the first things that should be done is to add fall protection equipment to your gear, in the form of a crash pad. These protective cushions are made from layers of foam, allowing a bouldering crash pad to provide a forgiving surface that softens tumbles and reduces the chance for broken bones, bruises and sprains. Fall pads can be expensive however, especially for people still deciding how involved they want to become in their new hobby. For these people who enjoy climbing but also like not breaking the bank (or their bones), The Foam Factory has the foam materials to assist in the construction of your own individualized crash pad.

Climbing is not a one-size-fits-all activity, so the creation of your own do-it-yourself pad is often a sensible decision. Every climber has their own preferences in climbing, so it only makes sense that they have their own requirements for what they need in a cushioning fall pad as well. The Foam Factory’s inventory of open and closed-cell foam materials provide a broad selection of feels and support to help you create a crash pad that fits your exact specifications.

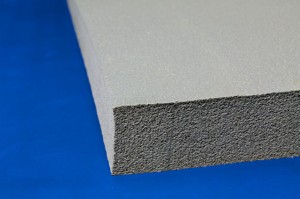

Made from layers of cushioning material with both closed and open-cell foam in their construction, crash pads combine foam types to achieve a balance of stability and cushion for climbers. The use of multiple types of safety foam is necessary to the performance of the product. Combining closed and open-cell foam provides a pad that functions much more safely than a pad made of any single material.

Tumble pads often stick to the same basics in design, with variations based upon a climber’s preferences and usage style. The typical design of a pad entails a 1 or 2 inch thick section of closed-cell foam layered atop 2, 3 or 4 inches of shock absorbing open-cell foam. Occasionally, designs add a third layer of closed-cell foam on the bottom to protect the pad against terrain and add height. The materials used in each layer are where the customization of bouldering pads takes place.

Closed-cell top layers in crash pads are imperative because of the stability they provide in a landing, combined with the dissipation of energy from the fall. That stability of closed-cell foam and foam rubber is important because many falls are controlled falls. When you are prepared to fall, you want a surface you can land on feet-first, without rolling ankles. The firmness of the closed-cell layer provides that while still having enough give to make these controlled falls easier on your joints. Polyethylene foam is the most popular foam material for this use. Resilient and shock absorbing, it easily handles the weight of a climber without giving them a jarring impact. It spreads the impact force through the material, so the material lasts longer as well. Polyethylene can be cut in solid thicknesses from ¼ of an inch up to two inches and sheets of polyethylene foam can be laminated together to create thicker, custom sections. The Foam Factory suggests 2.2 pound density for all-around performance at a great value, but high density foam varieties are also always available with values of 4, 6 and 9 pounds in-stock. Lighter, 1.7 pound density is also available for individuals looking to create different material combinations. Sheets are offered in dimensions of 54 by 24 inches, 108 by 24 inches and 108 by 48 inches. For an extra-firm top layer, gym rubber is also available in a variety of sizes and thicknesses.

Beneath the pad’s top layer is the section that provides the majority of a pad’s thickness as well as the cushion that provides safety from higher falls. Open-cell cushion foam making up the main body of the crash pad is a necessity, not only for protection when attempting climbs to greater heights, but also for the cushion it provides in unplanned, out of control falls from any height. The firmness of closed-cell foam provides stability, but on its own, it may not be enough to prevent injury in an unplanned fall. The thicker open-cell foam padding in the interior of a bouldering mat is what handles heavy impacts and makes the difference between waking up sore and possibly waking up in the hospital.

To handle falling, full-body weight in repetition, the open-cell interior must be firm enough to support that weight while still having the yield to provide the cushioning it is designed for. Old foam, used foam or even new foam that isn’t strong enough can open the possibility of bottoming out, which carries the same consequence of not having any pad, since you are falling through the cushion to the first resistive surface; i.e.: the ground.

To strike that balance of softness and strength, The Foam Factory suggests Lux-HQ foam for its ability to stay firm under compression, while cushioning rough landings. Lux-HQ is available in solid sections from 1/2 of an inch up to 8 inches and comes in sheets 82 inches wide with lengths of 24, 36, and 76 inches available depending on thickness. While you wouldn’t want a material too soft to protect against a fall, overcompensating with a foam that is toofirm can also be a problem. The inability to cushion and absorb makes for a landing area too similar to the ground you’re trying to avoid falling on. Foam like Lux-HQ is the right blend of resilient firmness and cushioning softness with the durability to last and give you safer bouldering falls.

In addition to Lux-HQ, The Foam Factory also stocks Dryfast foam, a material designed to drain water and resist bacterial, mold and mildew growth that is soft enough for cushioning protection. For extra prevention against rolled ankles and wrists, foam can be tapered or beveled to combat potential injuries caused by abrupt mat edges.

Climbing and bouldering can be exhilarating and challenging and is a great way to stay active. However, safety still needs to be the most important factor when climbing, no matter what. To help you get the most out of your climbs, The Foam Factory’s materials will help you create a covered foam crash pad tailored to your exact needs.

*Always be sure to check with local business and construction regulations before the purchase and installation of materials.

NOTE: This information is provided at your own risk. The Foam Factory is not responsible for injury, death or loss arising out of the use or misuse of our products. The Foam Factory will not have any liability to anyone for incidental or consequential damages or any other liability, injury, loss or damage arising out of or related to our products, even if The Foam Factory or an authorized representative of The Foam Factory has been advised of the possibility of such damages.

Tags: Crash Pad, DIY, Foam Pad, Gym Rubber, Lux Foam

Posted in Health and Fitness

How much does it cost to make my own crash pad?

Thanks

Hi Kurt,

This is a difficult question to answer, if only because building your own crash pads gives you the opportunity to customize them to the type of climbing you do, and the size and padding you feel is right for you could be totally different from the next person. There are also the covering materials you need to protect the cushioning, and whether you choose to DIY that, or outsource its sewing and construction has an impact on cost as well.

However, if you have a pretty good idea of what you may want to put together, visit our Contact Us page and shoot us a message – we’ll see what we can do for you!

– Foam Factory

Any thoughts on how thick the pad should be for every foot of rise? I’ve got a wall that’s about 9′, and my best guess would be for 3″ foam, but I don’t know if that’d be too shallow (or if it’d even be too deep for what I need).

Thanks!

We suggest 2″ of 2.2LB Polyethylene foam on top of 4″ of firm Lux Regular foam for your application.

Is it easy to keep the layers from sliding around, or will I need to glue them together somehow?

Thanks again!

We do suggest that the foam is glued together. Our 3M Super 77 spray adhesive is suggested for your application.

I just built a rock climbing wall in my garage. I would like to lightly pad about 90 sq/ft of floor (three 6×6 sections). I have two Black Diamond crash pads which will be placed under the primary fall zone of a section when I climbing it, but would like to pad the entire surrounding area to prevent elbows, knuckles, knees, and feet from hitting the concrete. My thought was to lay down a 6×6 tarp, then a layer of carpet padding, then 2 inch of closed cell polyurethane, then a piece of remnant carpet, then I would top it off with my Black Diamond Pads. I could slide the sections around on the tarps when I wanted to move them. My local foam store wants $300 for the 102x80x2 inch polyurethane foam which seems like a lot. I just wondering if anyone has a better suggestion for me. Foam Factory seems to have the best prices, and the name comes up a lot in bouldering forums.

Thanks for any help you can provide.

Our Lux Regular polyurethane foam is suggested for your application, along with our 2.2lb polyethylene foam.

I am building a crash pad for an aerial gym where the max height is 16 feet. Do you have a recommendation on the layers? Thanks

Typically what is used is 2″ of 2.2lb density polyethylene foam over 4″ of Lux Regular foam.

I am looking for a pad for aerial drops at a max heigh of 5 feet for under a yoga hammock. Do you have recommendations? I know this is a limited fall range but it’s on a hard floor.

You could go with a rock climbing setup, which uses 2″ of 2.2LB Polyethylene foam over 5″ of Lux Regular foam. Be sure to test to see if this will work for your application.

Interested in buying foam from you for a 9ft tall bouldering room 15ftx15ft. What’s your recommendation for layering and do you sell a product to go over the foam? Since it’s goin to cover the room entirely we wanted to cover it in the same way a gym mat is covered.

Thanks!

Usually what is used is 2″ of 2.2LB polyethylene foam over 5″ of Lux-High Quality foam.

Is there a standard for how thick mats should be for every foot of rise so I can set height parameters for a climbing rope? Does anyone know who sets these standards?

Hi, I was wondering if you were able to supply some foam padded mats for a manufacturing company.

Yes, please contact us for more information.

I’m looking to build a trifolding 84”x48” crash pad with three foam layers laminated together. I’m looking to shed a little weight since the size is bigger understanding that it will be a stiffer pad with the bottom layer.

First layer would be 1.25 in 2.2 lb polyethylene

Second layer would be 2.5 in lux-hq

Third layer would be .25 in 2 lb polyethylene

Each of the three blocks would be cut 28in x 48in so that when folded out I would have a crash pad that would be 84in x 48in

I was curious about what the approximate cost might be and if you have any thoughts on foam selections or if dimensions seem strange.

Feel free to email me back

Please contact us directly for suggestions and pricing information.

This is a great article yet posted in 2012. In 2019, is the ” 2″ of 2.2lb density polyethylene foam over 4″ of Lux Regular foam” still the recommendation? I have a home climbing wall that only about 8′ high by 20′ long and I’m in need of padding to go the full 20′ length and would like to know your 2019 recommendations.

Yes, this setup is still suggested.

I really messed up my knee and am stuck at home for the next month while I rehab in preparation for surgery (torn ACL, LCL, PCL, some other smaller stuff, along with a damaged peroneal nerve). The only way I can get comfortable outside of laying in my bed, is a really old Metolius crash pad that I put on the floor and sit on. It’s 10+ years old and pretty beat up, so I’m on the lookout for a replacement.

I know this isn’t really a crashpad (at least in the traditional sense) question, but what would you suggest? I don’t boulder anymore, and have no plans on starting again, so this wouldn’t receive the same type of impact generated by falls.

The closest available we have to that product is our 2.2LB polyethylene foam or Minicel Type T foam, 2LB density.

I’m building an indoor bouldering wall and can’t find any mats. Do you know ny sites that are cheap?

You could make your own. Suggested foam is 2″ of 2.2LB polyethylene foam on top of 4″ of our firm Lux-Regular foam. Then the foam could be glued together with 3M Super 77 spray adhesive.

I’m working with a Cross Fit Gym to build a climbing wall in a humid environment that doesn’t have A/C. I’m curious if the Quick Dry foam would work similarly to the Recommendation you made earlier for “[..] 2″ of 2.2lb density polyethylene foam over 4″ of Lux Regular foam.” The height of the bouldering wall is 16ft and the size of the pad that we’re looking to make is 24ft by 9ft (3 8ft by 9ft sections) Do you have any suggestions regarding the material? It’s very hot in the gym and humid and I’d be concerned about pads getting heavy, or moldy over time. Thoughts on materials for covering or someone who could sew the cover? Thanks for your time!

You could use 4″ of dryfast foam in place of 4″ of Lux foam. However the 2.2lb density polyethylene is still suggested. The Polyethylene foam is a closed cell foam, so it will be resistant to absorbing moisture. Cover suggested would be a vinyl for durability. A local upholstery shop may be able to assist you in making the cover.

Hi there,

I am starting my our training facility and I am going to purchase an 8×12 board, for it suggests I used either an 8-12′ thick foam mat? Look forward to hearing back! : )

Typically what we suggest is 2″ of 2.2LB polyethylene foam on top of 4″ of our Lux-Regular firm foam. You could go thicker on the 4″ Lux-Regular foam to fit your needs.

Hi – How did this set-up work for your gym?

With the 2″ of 2.2LB layer on top of the 4″ of Lux-R, what is the surface like for walking on? Will it last a while? Should it be covered with a fabric or something?

Life should be about 8-10 years with that setup. Yes we do recommend covering the foam with a durable fabric to extend the life of the foam.

I see your standard recommendation for bouldering wall padding is “2″ of 2.2LB layer on top of the 4″ of Lux-R”. I’m protecting a steep wall that can result in falling directly on my back, instead of my feet. Is this setup of foam soft enough? If not is there another softer foam that you recommend I place on top?

This setup is still suggested for your application.

I’m planning to make some crash pads for a home bouldering gym. The sizes would be approx 56×59 inches and 32×59 inches. Could you help? The 108×48 size could probably work. Thanks!

For specific questions, please contact usdirectly.

Hi,

We are building a home bouldering wall in our basement. We are looking for foam to fit inside a 72″ x 48″ x 8″ thick cover. From discussion on your site, it sounds like you recommend 2.2 lb polyethylene foam over Lux foam. Would you suggest 2″ of the polyethylene over 6″ of the Lux or a different ratio? Height of wall is 8′ with 30 degree angle. How do I get a quote for this? What would be cost of shipping to Portland, Oregon (97214).

Thanks!

The setup you have mentioned is good. Please contact us directly for pricing.

How much would it be to bond the 8″x76″x82″ to a sheet of the 2.2 lbs. closed cell foam of the sam size and ship it to Denver? I can probably make a cover.

We would be unable to ship that item. We can provide the items individually, the polyurethane foam, polyethylene foam and the adhesive to bond it together.

Hello, I’m building an indoor monkey bar/Ninja Warrior/swing set/zip line/rock climbing system for my small children and am looking to make a crash pad underneath these structures (the space to cover with the crash pad is about 16.5 feet wide and 10-12 feet long). My ceiling is 8ft. I see you suggested 2″ of 2.2LB layer on top of the 4″ of Lux-R for bouldering. What suggestion would you make for my situation? Thank you for your help!

We would suggest 5″ of HD36-HQ foamover 5″ of Lux-HQ foamfor your application.

Can you explain why in this case you recommend 5″ of the HD36-HQ instead of the 2.2lb polyethelyne foam as the top layer? The max fall height is equal to or less than other posts where you recommend 2″ of 2.2lb closed cell on top of 4-5″ of Lux-R open cell. Thanks for clarifying!

For bouldering crash pads, we recommend a top layer of 2.2lb PolyethyleneFoam and a bottom layer of Lux-HQFoam.

Hi, could we get a quote for the 8” foam plus 2.2” top foam for our home climbing wall. The dimensions of our wall are 15.83’X23.33’. Also, this would need to be shipped to Bend, Oregon.

Thanks!

Please Contact Usfor more information and pricing for you request.

I have an indoor bouldering wall with a single

Layer of crash pads underneath. I’d like to have a thick softer piece of thick foam over top to provide a more cushions landing, sometimes on my back. What kind of foam would you suggest? I’m thinking 6” thick (9’x6’). Would the Lux-HQ do the trick? I don’t think that I need to layer open and closed cell foam if I already have bouldering pads underneath correct?

The Lux-HQfoam may work, but you would have to test it for your application. Typically, the closed-cell foam would be on top to absorb the shock from the initial hit, and the open-cell foam is underneath for cushioning.

I have heard that for young, light, children, the stability layer can be less stiff or thick. Would 4″ Lux HQ + 1.5″ Polyethylene make a good crash pad for an 8ft tall bouldering wall I am building for my children? Also the surface beneath is carpeted floor. Or is there an other suggestion for making the pad slightly softer for children?

Yes, the 4″ Lux-HQwith the 1.5″, 2.2lb Polyethylenefoam is what we would recommend.

Hello,

I’ve been looking at making at DIY judo crashmat for high-impact throws, and the information above is great. Understandably, we take our landings in our back and side of legs: would the 2″ thick 2.2 lbs. polyethylene and 4″ regular lux foam still be ideal for a judo crash mat? Thanks!

Contact Usfor more information regarding your inquiry.

I have a 14’ tall climbing wall. What combination would you recommend?

For your application, we would recommend a two layer mat. The bottom layer would be our 6″ Lux-HQfoam. The top layer would be 2″ of our 2.2lb Polyethylene Foam. Feel free to Contact Uswith any further questions!

Hi, I am replacing the 2″ open cell foam from one of my crash pads. I was wondering if you would recommend the use of your high resilience foam. While more expensive, it seems like it may both protect the falling climber and have longer durability. Let me know if for some reason this foam isn’t appropriate for this application.

Please Contact Usfor further information regarding your inquiry.

I am building an indoor climbing wall for my young kids (oldest is 3) and would like a crash pad that will work now but is modular for the future. The wall is 4’ wide x 8’ tall. I gather that for little ones who can’t predictably land on their feet, 5” of HD36 on top of 5” Lux is great, but as they age and learn to land on their feet, a stable top of 2.2 lb PE or Minicel T200 (1.5-2”) is good to prevent rolled ankles.

I am thinking a good compromise might start as 4” HD36 on top of 4” Lux on top of 2” 2.2 lb PE (in individual 1/2” sheets). This would work for now, but would allow the flipping of the pad once they can land on their feet, and with individual PE sheets, I could hone in on what’s best for lightweights (1”, 1.5”, or 2”) to give that stable platform that isn’t too rigid for a lightweight (having the remaining PE on the bottom).

Does this seem like a good setup?

I’m also hoping you can make me a custom cover to house this.

Thank you for reaching out to us via our blog.

Per your question, we are only able to provide the materials, so you would have to figure out what you need and assemble on your end. We also do not offer covers for these pads.

For a climbing crash pad, solid foam is actually recommended. It is usually a two layer piece. The first layer is 1-2” of our 2.2lb Polyethylene foam. This foam is what will absorb the shock of the fall. The second layer is 5-6” of our Lux-HQ. This is a softer foam that is what cushions the fall to prevent injury.

For younger ones you can use the HD foam in place of the LUX foam. However, you typically do not need to use both foam types. We do suggest to add the Polyethylene foam for the shock absorption layer. But based on the weight of your children, you can use a thinner version of this foam.

Something of this size is not something we normally work with, and none of our foams have been specifically tested for this application, so we can only base our recommendations off of what we have seen customers use in the past, and what is recommended by the industry. Our typical recommended crash pad is an 8-10 thick piece made up of two layers. The top layer would be 1-2” of a closed cell, 2.2lb Polyethylene foam for shock absorption, and a 6-8” bottom layer of softer Lux-HQ foam, which is what pads the landing. This is the typical combination for rock climbing crash pads.

For all future questions please contact us.

Hi FF, I thought I’d ask my question here, since you seem pretty responsive, and your response may help future visitors.

I weigh about 175 lbs. at the moment (but can fluctuate up and down 10-20 lbs.), and I built a climbing wall in my home that is almost 11′ tall. While I see your recommendation that 1-2″ of the closed cell 2.2 lbs. PE foam over 3-4″ of your open cell Lux HQ is suitable, how do I modulate the overall thickness of the pad and the thicknesses of the 2 foams based on my wall height, projected climber weight, preferences, etc.?

Any personalized recommendations for my current setup, as well as general tips on how to determine the best foam thicknesses (for future builds) would be appreciated!

What is popular is 2″ of PE on 4″ of Lux-HQ. Your weight is average, so I would suggest this setup for your application.

Hi FF, I plan to construct a bouldering room for our club. There would be a 9′ drop from the top, would a 2″ 2.2 lb CC PE Foam + 4″ OC Lux HQ Foam suffice?

Also, are you able to ship bulk orders overseas?

Yes, that should work. Yes, we can ship overseas. Please contact us directly for a price quote.

Wonderful article!

I am trying to made my own crash pad for outdoor climbing, and is shocked by the high price. This article helps me to choose the most important material of the pad. Thank you so much. However, I am unable to buy the foams from Foam factory directly since I am aboard. I wonder the density of PE and LUX-HQ Foam? If I can directly choose the same density foams to replace them so I can purchase the foam in my loacl shop?

For a typical bouldering pad design like organic, its structure is like a sandwich. Will you recommend to add a layer of foam at the bottom? If so, what type of foam should I choose.Moreover for a pad for outdoor activity, I should consider the weight? Can I choose foam with higher density to reduce the thickness?

Any recommendations will be appreciated!!!

The Lux-HQ foam is a 2.8LB density and 50LB ILD. The polyethylene is a 2.2LB density. Typically the polyethylene foam on the polyurethane foam is sufficient. 2″ of polyethylene over 4″ of polyurethane foam.